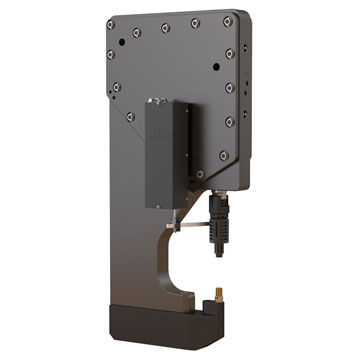

The thin design of the Bottom Anvil Presses offers simplified, flexible and cost-effective solutions. BTM clinching capabilities and our expertise in assembly technology can help you improve operator efficiency in high demand metal joining applications.

Key Specifications | |

|---|---|

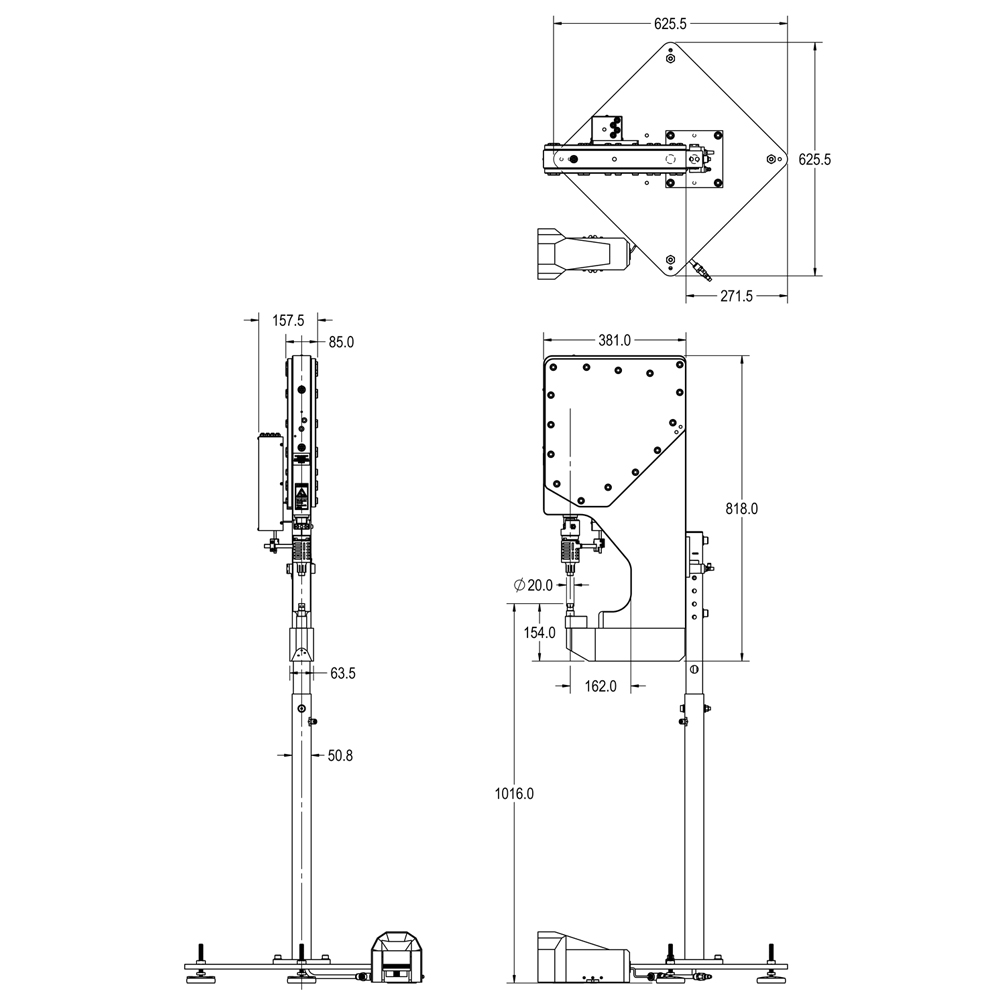

Maximum Combined Material Thickness | 4.0 mm [Mild Steel] |

Throat Depth | 150 mm |

Maximum Stroke | 76 mm |

Cycle Time | 1 second |

Weight | 52 kg [115 lb] |

Standard Input Pressure | 5.5 BAR [80 PSI] |

Tool Size | 3.0 to 4.6 |